Introduction to Wood Finishes

Wood finishes play a crucial role in both the protection and the aesthetic enhancement of wooden surfaces. They serve as a barrier against environmental factors such as moisture, UV rays, and physical wear, ultimately prolonging the health and longevity of wood products. In addition to their protective capabilities, finishes can significantly influence the visual appeal of wood, bringing out its natural grain patterns and colors. Understanding the various types of wood finishes is essential for selecting the appropriate one for your project.

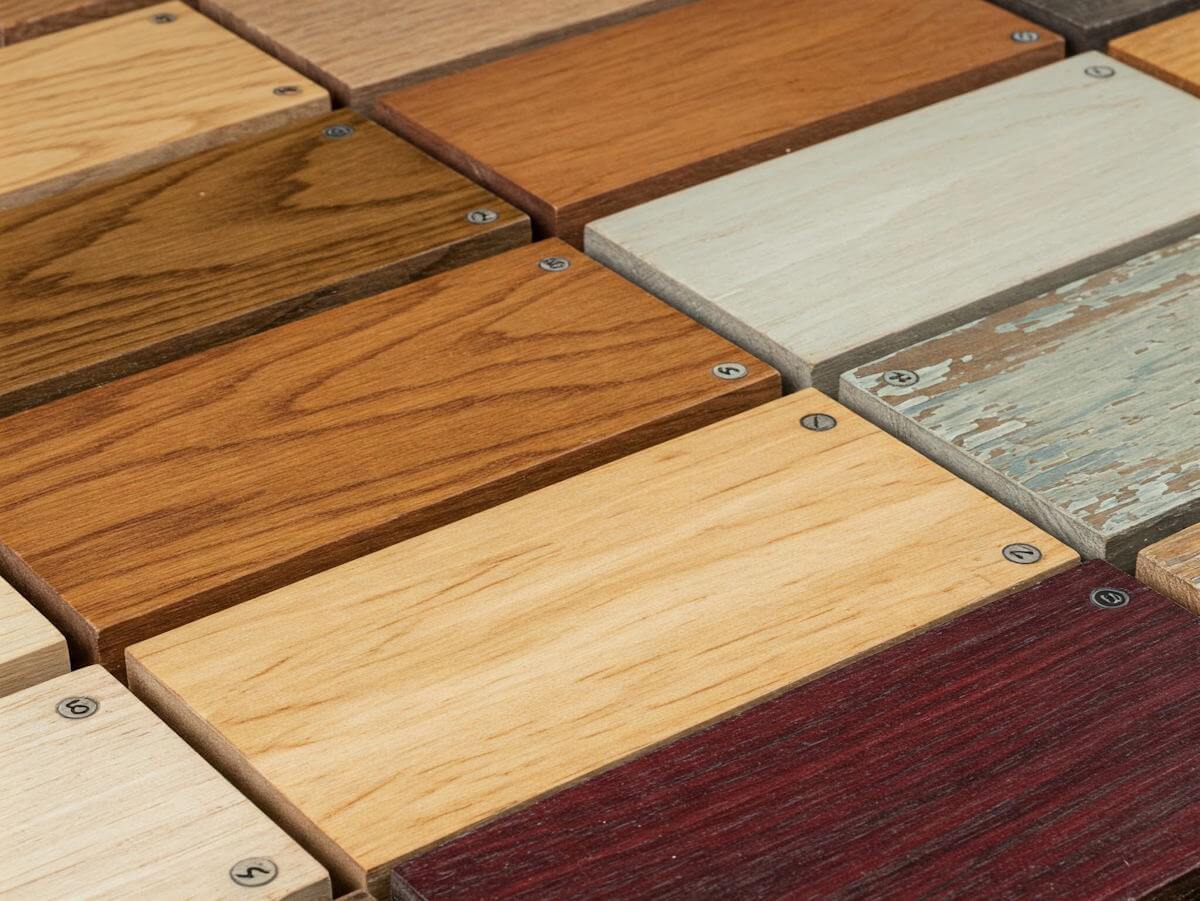

There are several categories of wood finishes, each with distinct properties and applications. Oil-based finishes, for instance, penetrate the wood fiber deeply, providing a rich, warm glow while offering excellent durability. Common examples include tung oil and linseed oil, which cure over time and enhance the natural beauty of the wood. On the other hand, water-based finishes are growing in popularity due to their quick drying time and low VOC emissions, making them suitable for indoor use where air quality is a concern. These finishes are available in a range of sheens, from matte to high gloss, allowing for versatility in design.

Varnishes are another widely used category, known for their robustness and resistance to water and solvents. They create a hard, protective film on the wood surface, making them ideal for high-traffic areas or outdoor furniture. Stains, while not a protective finish on their own, are often applied underneath a clear coat to enhance the wood’s color. They come in various hues, allowing for customization according to personal preferences. It is vital to choose the right finish based on the type of wood and its intended use, as this selection impacts both the performance and aesthetics of the final product.

Understanding Different Types of Wood

When selecting a finish for wood projects, it is vital to understand the various types of wood available, which can be broadly categorized into hardwoods and softwoods. Hardwoods, such as oak, maple, and cherry, are generally derived from deciduous trees. They are known for their durability and complexity in grain patterns. Oak, for instance, features a prominent grain that can enhance the aesthetic appeal of finished products. Maple, with its finer and more uniform grain, is often used for furniture and cabinetry. Cherry wood, renowned for its rich, warm tones, also deepens in color over time, making it a desirable choice for many craftsmen.

On the other hand, softwoods like pine and cedar come from coniferous trees. While they are generally less dense and lighter than hardwoods, softwoods offer their unique advantages. Pine is often favored for its affordability and versatility, as it accepts stains and finishes exceptionally well. Its fine knots and pale color can introduce a rustic charm to furniture. Cedar, recognizable for its distinctive aromatic qualities, is valued for its natural resistance to decay and insects, making it an excellent choice for outdoor projects. Its reddish hue and fine grain make cedar beautifully distinctive when finished appropriately.

Understanding the characteristics of each wood type is crucial. Factors such as porosity, grain patterns, and natural color variations significantly influence how a finish will adhere and appear on the surface. For example, porous woods like oak may require a sealer before applying a topcoat to prevent excessive absorption of finish products. In contrast, the smoother surfaces of maple might not need such treatment. These considerations deserve careful attention to achieve the desired aesthetic and functional outcome in woodworking projects.

Factors to Consider When Choosing a Finish

Choosing the appropriate finish for wood is contingent upon several critical factors that directly influence both the aesthetic appeal and durability of the final product. Understanding these elements is essential for ensuring that the chosen finish meets the specific requirements of each project. One fundamental consideration is the wood’s grain structure. Different woods exhibit varying grain patterns, which can affect how the finish interacts with the surface. For instance, open-grained woods such as oak may require a thicker finish to fill in the pores, whereas tight-grained woods like maple might showcase better results with lighter finishes.

Another significant aspect to take into account is the environment where the wooden item will be utilized. Finishes designed for interior use may not withstand the elements outdoors. Conversely, exterior finishes are formulated to resist moisture, UV damage, and temperature fluctuations. Therefore, evaluating whether the wood will reside indoors or outdoors is essential in selecting an appropriate finish.

The desired aesthetic plays a crucial role in the decision-making process as well. Some finishes enhance the wood’s natural color and grain, while others alter its appearance entirely. For instance, oil-based finishes tend to provide a warm glow, highlighting the wood’s unique characteristics, whereas paint offers a uniform color but obscures the grain. Additionally, durability requirements should not be overlooked; a high-traffic area may demand a finish that can withstand wear and tear over time without sacrificing its visual appeal.

Lastly, the ease of application can be an influencing factor, particularly for DIY enthusiasts. Some finishes require more skill and time to apply than others, which can determine the choice based on the users’ comfort level and project timeline. Evaluating these elements collectively can guide individuals toward selecting the right finish that aligns with their specific project needs.

Popular Wood Finishes and Their Applications

When it comes to enhancing the beauty and longevity of wood, selecting the right finish is essential. Various wood finishes cater to different needs, offering unique benefits and drawbacks. Below are some of the most popular wood finishes and their applications.

Oil Finishes, such as tung and linseed oil, penetrate deeply into the wood grain, nourishing the fibers while providing a warm, natural look. Tung oil is particularly favored for its water-resistant properties and durability, making it ideal for furniture and outdoor applications. Linseed oil, on the other hand, requires longer drying times and may need more frequent reapplication but is excellent for rustic finishes.

Water-Based Finishes represent a modern choice that prioritizes environmental safety. They dry quickly, have low volatile organic compounds (VOCs), and offer a clear finish that does not yellow over time. This type of finish is suitable for light-colored woods such as maple and birch, and it is commonly used for indoor furniture and cabinetry.

Polyurethane is a highly durable finish available in both oil-based and water-based options. Oil-based polyurethane dries slowly and adds a warm glow, while water-based variations dry faster and are less odorous. The versatility of polyurethane makes it compatible with various wood types, including oak and cherry, providing excellent protection against scratches and stains.

Lacquer dries quickly and produces a hard, high-gloss finish often favored for its aesthetic appeal. It is adept at showcasing the natural beauty of the wood, making it a popular choice among cabinetmakers. However, lacquer requires careful application due to its flammability and sensitivity to humidity.

Varnish offers a robust protective layer against UV rays and water. It is available in several sheens and is suitable for both interior and exterior applications, particularly on hardwoods like mahogany and teak. Although it takes longer to dry, varnish is known for its longevity and resistance to wear.

Shellac is a traditional finish that provides a warm tone and can be easily repaired. However, it is not as resistant to moisture, making it better suited for indoor projects. It is often applied on fine furniture and antiques and can be used as a base coat for other finishes.

Understanding the characteristics of these wood finishes is crucial in making an informed choice. Whether prioritizing durability, aesthetics, or easy application, there is a suitable option for every woodworking project.

Matching Finishes with Hardwoods

Choosing the appropriate finish for hardwoods is crucial to enhance their natural beauty and durability. Hardwoods such as oak, walnut, and maple have distinct characteristics that influence the selection of finishes. Oak, known for its prominent grain patterns and durability, is often complemented with both oil-based and water-based finishes. A clear polyurethane finish not only highlights oak’s natural texture but also provides robust protection against wear and tear, making it suitable for high-traffic areas.

Walnut, on the other hand, has a rich, dark hue and a fine grain that can be beautifully showcased with oil finishes. Danish oil or a tung oil finish penetrates deep into the wood, enriching its color while maintaining a natural look. This type of finish also allows the wood to breathe, preventing any adverse reactions over time. For a more polished appearance, satin or gloss polyurethane can be applied, enhancing walnut’s sophistication while offering considerable protection.

Maple, with its light color and subtle grain patterns, can benefit from a finish that accentuates its brightness. Water-based finishes are a preferred choice for maple, as they dry clear and prevent any yellowing that might occur with oil-based products. This helps maintain the wood’s light aesthetic. Additionally, a matte or satin finish can be applied to develop a natural, understated look that aligns with contemporary design trends.

In all cases, it is essential to consider the intended use of the hardwood. For furniture pieces, durability is paramount, while decorative items may prioritize aesthetics. Testing different finishes on scrap wood before application on a complete piece can ensure the best match, ultimately contributing to the enhancement of the wood’s beauty and longevity. Matching the right finish with hardwood not only preserves its integrity but elevates any project to the next level.

Matching Finishes with Softwoods

Softwoods, comprising species such as pine, cedar, and fir, present unique characteristics that significantly influence the choice of finishes. Generally lighter in density and softer in texture than hardwoods, softwoods can benefit from finishes that both enhance their natural beauty and provide protection against wear. When selecting a finish for softwoods, it is essential to consider factors such as the wood’s grain structure, stain absorption, and knot visibility.

Pine, for example, is known for its light color and prominent grain patterns. This wood species is particularly absorbent, which means it can take on stains and finishes quite readily. For pine, a clear wood finish like polyurethane can enhance its natural color while providing a durable surface. Moreover, using a pre-stain wood conditioner can help achieve a more uniform color by preventing blotchiness, which is common due to the variation in grain density associated with pine.

Cedar is another popular softwood, valued for its aromatic properties and rich reddish hue. The natural oils present in cedar can sometimes create challenges when applying finishes. Therefore, opting for oil-based stains or sealants is often advised, as they penetrate well and highlight the wood’s natural color. Additionally, a finish that protects against UV damage is essential for cedar used in outdoor applications to prevent fading over time.

Fir, known for its strength and stability, often features a straight grain with little variation. Finishes that bring out the grain, such as penetrating oils or matte varnishes, work well with fir. Given its lower resistance to moisture, applying a protective finish can help safeguard fir surfaces from environmental elements. Knot visibility is another consideration when finishing fir, as the knots can absorb finishes differently, resulting in visual discrepancies.

In conclusion, selecting the right finish for softwoods is crucial in preserving their natural aesthetics while ensuring durability. Understanding the specific properties of pine, cedar, and fir will guide crucial decisions regarding finish types and application methods to achieve the finest results.

How to Apply Wood Finishes

Applying wood finishes effectively requires attention to detail and a thorough understanding of the materials involved. Prior to application, it is crucial to prepare the wood surface properly. Begin by sanding the wood to remove any imperfections or rough spots. Use progressively finer grits of sandpaper, finishing with a grit level that ensures a smooth surface. Ensure to wipe down the wood with a damp cloth or tack cloth to remove dust particles, as these can interfere with the adhesion of the finish.

When it comes to the application of wood finishes, there are several methods, including brushing, rolling, spraying, or wiping. Each method has its own advantages and disadvantages. For instance, using a brush provides more control and allows for the application of thicker layers, but can leave visible brush strokes. On the other hand, spraying can achieve a more uniform finish but may require significant practice to master. Choose a technique that best suits your skill level and the complexity of the project.

Regardless of the method chosen, applying the finish in thin, even coats is essential. This practice helps prevent runs and drips, ensures better adhesion, and leads to a more aesthetically pleasing final product. Allow adequate drying time between each coat as specified by the product guidelines. For optimal results, consider lightly sanding between coats to enhance adhesion and achieve a smoother surface.

Furthermore, safety precautions should not be overlooked when working with wood finishes. Proper ventilation is critical, especially when using solvent-based finishes, as they can release harmful fumes. Always work in a well-ventilated area and consider wearing gloves and a mask for additional protection. Finally, once the finish is applied and fully cured, maintaining the finished surface will prolong its life. Regular cleaning and occasional reapplication of the finish will help maintain its appearance and functionality.

Testing Finishes Before Final Application

Before applying a finish to a woodworking project, it is imperative to conduct thorough tests on sample pieces of wood. This practice enables artisans to observe potential color changes, assess drying times, and evaluate compatibility with the chosen wood. By doing this, one can ensure that the finish will deliver the desired aesthetic and functional qualities in the final piece.

The first step in testing finishes is to gather a few sample pieces of the same type of wood that will be used in the project. It is important to select pieces that are representative of the characteristics of the larger surfaces. Sand the samples to a uniform smoothness using progressively finer grits of sandpaper, incorporating an initial grit of around 120 and finishing at 220. This initial prep ensures uniform absorption of the finish and helps achieve consistent results.

Once the samples are sanded, it is time to apply the chosen finish. Using a brush or cloth, apply the finish evenly to each sample, making sure to follow the manufacturer’s instructions regarding application techniques. It may be advisable to experiment with different application methods, such as spraying versus brushing, to see which yields the best results in terms of appearance and texture.

After the finish has been applied, monitor the samples for color changes as they dry. This step is significant since some finishes can alter the wood’s hue dramatically. Pay attention to the drying time as well, as different finishes vary in their drying characteristics. It’s crucial to allow ample time for the samples to fully cure, typically several days to weeks, depending on the type of finish used.

After the curing process, assess each sample for compatibility and the overall satisfaction with the finish’s appearance. Taking detailed notes during this testing phase can help in making a final decision on the finish most suitable for the project’s needs. By carefully testing finishes beforehand, one can achieve impressive results and avoid potential disappointments during application on the final workpiece.

Conclusion: Making Informed Choices

In choosing the right finish for different types of wood, it is paramount to consider multiple factors that affect both the appearance and durability of your projects. Throughout this discussion, we emphasized the importance of understanding the specific characteristics of various wood types, which significantly influence how they absorb finishes and how those finishes perform over time. Different woods, such as oak, pine, and cherry, present unique challenges and opportunities that can be optimized with the right finishing techniques.

Furthermore, the intended use case of the finished wood should guide your decisions. For instance, furniture that will experience wear and tear may benefit from a more robust finish, such as polyurethane, whereas decorative items may allow for a lighter touch with oils or stains that enhance the wood’s natural beauty. Aesthetic preferences also play a crucial role: whether you’re aiming for a modern, sleek look or a more rustic appearance, the finish chosen can transform the final product dramatically.

Importantly, we encourage you to experiment with different finishes to find out what suits your projects best. Every woodworker has a unique style and preference, which can only be discovered through hands-on experience. Learning from what works and what doesn’t is key to mastering the art of wood finishing. As you embark on your journey to finish wood projects, keep these considerations in mind and trust your instincts. The best finishes are those that not only meet functional needs but also resonate with your artistic vision.